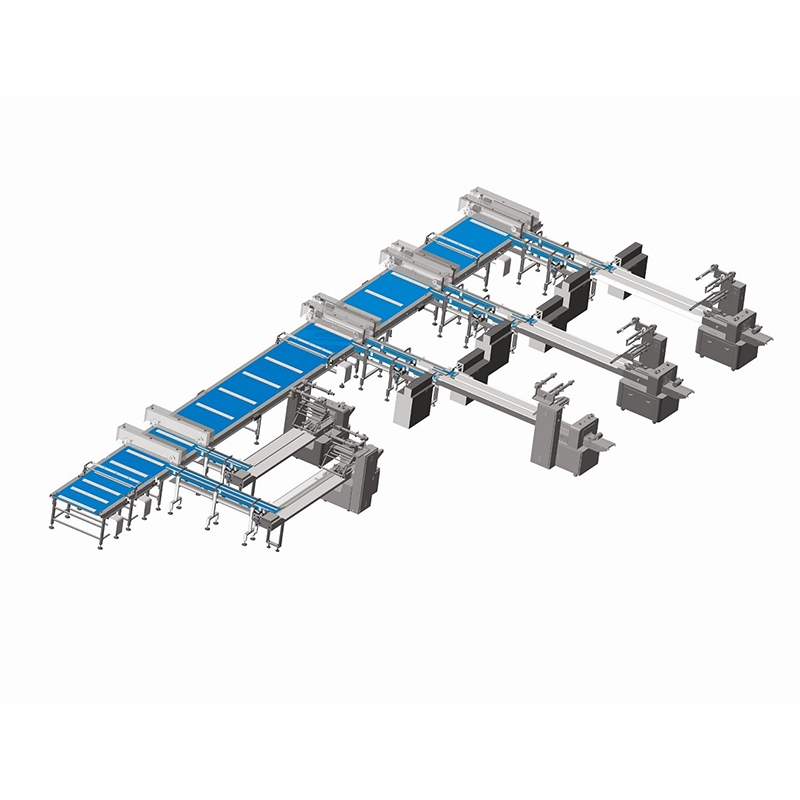

Otomatiki Wafer Packing Line L Type

Tsanangudzo Pfupi:

Iyi otomatiki wafter yekurongedza mutsetse inoshanda kune wafer uye zvimwe zvakafanana zvekucheka zvigadzirwa zvine hukuru hukuru, asi mukurongeka kwakanaka uye chimiro chenguva dzose. Inogadzirisa matambudziko echinyakare senge madaro ari padyo pakati pezvigadzirwa, yakaoma nzira yekutendeuka, kusagadzikana kuronga mumitsara, nezvimwe kuti uwane imwe chete kana akawanda kurongedza fomu.

Product Detail

Product Tags

Product Detail

Iyi otomatiki yekurongedza sisitimu yakagadzirirwa zvigadzirwa zvine tireyi kana bhokisi, uye iyi yekurongedza mutsara inogona kurodha tireyi nekurongedza pasina chero basa remanyorero.

Mumwe mushandi anogona kushandisa mitsara miviri, iyo inobatsira kuchengetedza mari yebasa kune vatengi.

Iyi yekudyisa-mukati uye yekurongedza mutsetse ine deoxidizer kana deoxidizing agent pad feeder, tray inoyamwa pasi unit, tray otomatiki yekurodha unit uye yekurongedza muchina.

Iko kumhanya kwekutakura kwetireyi yekurodha uye yekurongedza mutsara ndeye 100-120 masaga paminiti.

1. Chigadzirwa Chekutanga cheAutomatic Horizontal Wrapping Equipment yeSwiss Roll

Iyi wafer yekurongedza system ndeye yakawanda-inoshanda sisitimu, iyo inogona kurongedza imwechete wafer uye yakawanda-wafer. Isu takagadzira iyo yese yekurongedza sisitimu zvinoenderana nemagadzirirwo ako uye kubvunza. Iyo yakanyanya kumhanya inogona kusvika ku250 mabhegi / miniti. Kumhanya kwepakiti yemhuri kunoenderana nehukuru.

2. Basa guru reChikafu Packing Machine yeWafer

Iyo wafer yekurongedza mutsara ine chinhambwe chinodzora, chinodzosera chinodzosera, otomatiki yekuronga unit, uye yekurongedza muchina. Iyi sisitimu inozobatsira wafer auto kurongedza, kure, kugovera, uye kuendesa kune yekurongedza unit uye kupedzisa kurongedza kuitira kuchengetedza inoenderera uye yakarongeka kugadzirwa nemarara yakaderera uye yakanaka package. Doro pfapfaidzo uye kuchaja mhepo zvinosarudzika.

Single line kurongedza kumhanya inogona kusvika 80-220 mabhegi / min.

Iyo yese yekurongedza sisitimu inotora 220V, 50HZ, chikamu chimwe chete. Yese Simba iri 26KW

Iyo chikafu chekutakura sisitimu inogona kushandisa akasiyana ekutakura modhi zvinoenderana nemutengi chigadzirwa kubvunza.

3. Kubatsira kweAutomatic Food Packing System yeWafer Biscuit

Iyo yakatwasuka yekurongedza mutsetse yakashongedzerwa neauto aligning mudziyo uye chivharo chekudzivirira. Mudziyo wekugadzirisa otomatiki ndewekusarudza.

Chimiro chakareruka, kushanda kuri nyore, kuchenesa kuri nyore, uye kugadzirisa. Kugadziriswa kuri nyore kune zvakasiyana zvigadzirwa kana parameter marongero.

Iyo Kudzora sisitimu inoshandisa yemhando yepamusoro yemagetsi, yakangwara PLC, yekubata sikirini, uye yakanaka HMI, inoshanda zviri nyore uye zviri nyore.

Iyo inoyerera yekurongedza mutsetse yakashongedzerwa akati wandei akasiyana ekumhanya bhandi kuronga zvingwa kana makeke kuvimbisa kumhanya kwakanyanya kwakasimba uye kuwana nemazvo.

Iwo otomatiki chikafu chekurongedza muchina uye sisitimu inoshandisa simbi isina tsvina uye Nylon baffle, iri nyore kushanda uye kuchenesa.

Bhandi rePU rinogona kuburitswa pasina maturusi muminiti 1 uye rakashongedzerwa hopper kuti uwane tsvina yechigadzirwa, iri nyore kuchenesa nekugadzirisa.

Chimiro chemuchina wekudya chiri nyore, kushanda kuri nyore, kuri nyore kuchenesa nekugadzirisa. Kugadziriswa kuri nyore kune zvakasiyana zvigadzirwa kana parameter marongero.

Iyo Kudzora sisitimu yepurasitiki firimu yekurongedza midziyo inoshandisa yakakwirira-mhando yemagetsi, yakangwara PLC, yekubata sikirini, uye yakanaka HMI, inoshanda zviri nyore uye zviri nyore.

Isu tichawedzera 90-dhigirii inotenderedza conveyor kana 180-dhigirii inoshandura conveyor kune yekurongedza sisitimu zvinoenderana nevatengi 'fekitori marongero kana nzvimbo.

Yakashongedzerwa nemamita detector uye uremu chekutarisa, iyo inogona kubatana otomatiki neyekuyerera kurongedza system.

Wafer otomatiki chikafu chekurongedza muchina wakashongedzerwa neotomatiki yekumisikidza mudziyo uye otomatiki kugadzirisa mudziyo webhandi inosarudzika.

Mutsetse wekutakura unogona kuenzanisa wafers (zvigadzirwa) uye kuendesa kune yekurongedza unit zvakarongeka kuti ivimbise kumhanya kwakanyanya kwakadzikama uye kuiwana nemazvo.

PU bhandi remushini wekurongedza rinogona kuburitswa pasina maturusi uye rakashongedzerwa hopper kuti uwane tsvina yechigadzirwa, iri nyore kuchenesa nekugadzirisa.

Chimiro chakareruka, kushanda kuri nyore, kucheneswa kuri nyore uye kugadzirisa. Kugadziriswa kuri nyore kune zvakasiyana zvigadzirwa kana parameter marongero.

Iyo wafer line control system inoshandisa yakakwirira-mhando yemagetsi, yakangwara PLC, yekubata sikirini, uye yakanaka HMI, inoshanda zviri nyore uye zviri nyore.

Iyo PU bhandi rewafer yekurongedza tambo inogona kushandisa inonamira chiratidzo mune chena ruvara sarudzo.

4. Kushandiswa kweAutomatic Packaging Machinery

Inoshanda pakurongedza chikafu chakawedzera uye chimwe chigadzirwa chenguva dzose, icho chinogadzirwa nemichina yekucheka. Yakabatanidzwa neyaimbova mutsara wekugadzira neatomatiki feeder kana manual feeder.

5. Packaging Samples

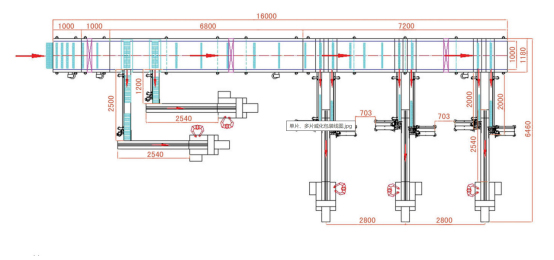

6. Kudhirowa kwe Automatic Packaging Solution

7. Packaging System Details.

(1) Distance controller

Basa guru remutongi wedaro kudhonza pamusoro pechigadzirwa chinhambwe kana kuzvichengeta mumitsara.

(2) Kugovera conveyor

Iyi yekuparadzira inotakura yemhinduro yekurongedza inoshandiswa kuendesa zvigadzirwa mumitsara yekurongedza yakasiyana. Kureba kwezvikamu izvi kunoenderana nekukwanisa kwevatengi kugadzira kana marongero efekitori.

(3) Direction pusher

Iyo inotungamira pusher inowanzo shandisa chete yewafer yekurongedza sisitimu, iyo inobatsira kushandura iyo wafer kutungamira uye kuendesa kune yakasiyana yekurongedza muchina.

(4) Bhandi rekuchengetedza

Basa guru rekuchengetedza Bhandi ndere kuchengetedza iwo mawafer uye kubatsira kuendesa kumuchina wekurongedza, kupedza kurongedza.

(5) Servo pusher

Nhanganyaya: Iyi servo pusher inongoshandisa chete kune yemhuri wafer yekurongedza mutsara. Nekurongeka mazwi, kana iwe uchida 6pcs pabhegi (2layer uye yega yega 3 zvidimbu), ipapo chikamu ichi chinoda kuronga. Kana iwe uchingoda kurongedza imwechete wafer, saka hapana chikonzero chezvikamu izvi.

Basa: Basa guru nderekusundidzira boka wafer muinfeed conveyor, wozoisa pasuru.

(6)Kuronga chikamu

Kuronga chikamu chekurongedza sisitimu yekusuma:

Iyo yekurongedza zvikamu zvikamu zvine 2 mabhandi ekutakurisa uye 5-6 sensors.

Basa rekutangisa unit:

Basa guru reiyi yekurongedza unit ndere kudzora chigadzirwa chekudyisa kumhanya, kuchiisa, uye kuchibatanidza nemuchina wekurongedza otomatiki. Kana yangoona chigadzirwa chakawandisa, kukurumidza kwekudya kunononoka, kana kushaikwa kwechigadzirwa, ipapo kukurumidza kwekudya kuchataura nekukurumidza.

Kubatsira kweiyo yekuronga unit:

Kuderedza kushanda kwevanhu uye ita shuwa kuti muchina wekurongedza unoshanda nekumhanya kwakagadzikana uine mashoma zvigadzirwa tsvina.